Repair On An Industrial Diesel Hot Pressure Washer For A Haulage Company in Dover

What they needed

We were asked to carry out a major repair on an industrial diesel hot pressure washer for a haulage company in Dover. The machine is used regularly for vehicle cleaning and had developed multiple faults due to long-term wear and a lack of preventative maintenance.

The unit was no longer operating reliably and required a full inspection and mechanical overhaul to restore performance.

Problem / Requirement

- Machine type: Industrial diesel hot mobile pressure washer.

- Main issues: Multiple mechanical and burner-related faults caused by wear and insufficient servicing.

- Symptoms: Reduced performance, starting issues, fluid leaks, and unreliable hot water operation.

- Operational impact: Downtime affecting vehicle cleaning and fleet maintenance.

Several components had deteriorated simultaneously, leading to wider system failure.

Our Solution

- Removed and externally repaired a leaking radiator.

- Stripped, cleaned, and fully serviced the diesel burner assembly.

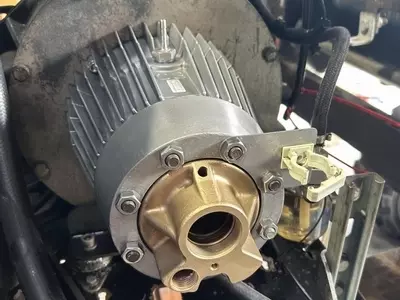

- Completely rebuilt the high-pressure pump with new seals, valves, and internal components.

- Replaced engine and pump fluids throughout.

- Renewed all filters.

- Replaced cracked and worn pipework.

- Replaced a faulty capacitor and recalibrated engine speed.

- Fitted a new starter motor and checked glow plugs.

- Replaced the failed pump-to-engine drive shaft.

- Drained, flushed, cleaned, and refilled the fuel tank with fresh diesel.

- Reassembled, pressure tested, and fully commissioned the machine.

The Result

- The industrial diesel hot pressure washer is now running smoothly and reliably.

- Burner performance restored for consistent hot water output.

- Pump rebuilt to full operating condition.

- Electrical and starting faults eliminated.

- Leaks resolved and fuel system refreshed.

- The machine is back in daily service supporting the haulage fleet.

This repair demonstrates the importance of preventative maintenance. Addressing wear early prevents costly breakdowns and extended downtime.