Nilfisk SC Uno + Backup Nilfisk DTE Installation For A Logistics Company In Ellistown

What they needed

We were asked to supply and install a new high-performance pressure washer system for a logistics company in Ellistown. The customer relies heavily on pressure washing for pallet cleaning and wanted more power along with a reliable backup solution as part of their move to a larger site.

Problem / Requirement

- Existing machine: The company already had a DTE pressure washer from their previous site.

- Main issues: The existing DTE unit didn’t provide enough power for the increased workload at the new facility.

- Site conditions: A dedicated wash booth was already built, and the customer needed a clean, organised setup without hoses trailing across forklift routes.

- Usage: Frequent daily pallet washing as part of ongoing logistics operations.

The customer needed a more powerful primary machine, with the original DTE retained as a backup to prevent downtime and production delays

Our Solution

- Supplied and installed a Nilfisk SC Uno to provide a higher-powered primary washdown system.

- Reallocated the existing DTE pressure washer as a dedicated backup unit to ensure continuity in the event of a breakdown or service requirement.

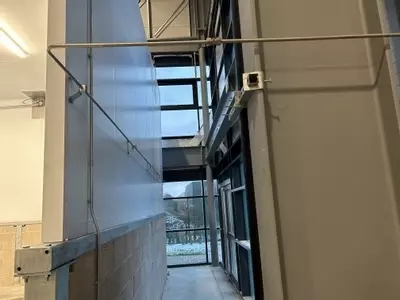

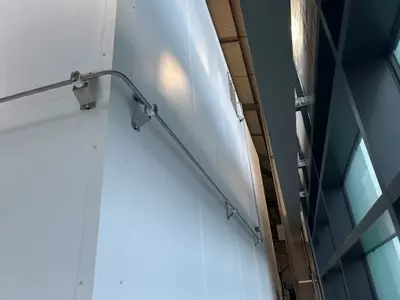

- Ran high-pressure pipework around the rear of the wash booth to feed the washing area cleanly and safely.

- Connected the system to a wash boom, preventing hoses from lying on the floor or being driven over by forklifts.

- Constructed UniStrut frames and mounted both machines securely to the building structure so they were level, organised, and off the ground.

- Positioned the machines for easy access, making servicing, maintenance, and operation straightforward.

The Result

- The Nilfisk SC Uno provides increased power and performance, improving pallet washing efficiency.

- The original DTE unit now serves as a reliable backup, reducing the risk of downtime and supporting continuous operation.

- The wash boom and rear pipework eliminate hoses on the floor, preventing damage from forklifts and creating a safer, tidier workspace.

- The UniStrut mounting keeps both machines secure, level, and easy to work on, improving long-term maintenance and usability.